What are the sustainability advantages of flexible packaging?

Flexible plastic packaging has many sustainability benefits over rigid plastic packaging. These sustainability benefits as well as the associated economic benefits have led flexible packaging to be the quickest growing segment of the packaging market in recent years, think chips bags and drink pouches among the vast variety of flexible plastic packaging on the market. Flexible packaging allows for multiple layers of polymers to meet the exact technical needs of product packaging in order to maximize product shelf-life and integrity (Association of Plastic Manufacturers). Flexible packaging allows for material use reduction per product, reducing the overall need for plastic packaging per product. Its lightweight nature reduces the required transportation energy and emissions as well. Flexible plastic packaging has many inherent sustainability benefits that can only be increased by taking extra measures to improve its end-of-life impacts through design for recyclability, increased use of recycled content, and innovations in compostability.

How is flexible plastic recycled?

When discussing recycling, a distinction has to be made between household waste and industrial waste. Industrial waste is not comparable to household waste as it is usually collected through private agreements between waste management companies and industrial manufacturers. This form of recycling benefits from the efficient collection of uniform, clean, and well-tracked plastic material. On the other hand, flexible plastics collected from many different households (also known as post-consumer plastics) require many extra steps in order to prepare them for recycling.

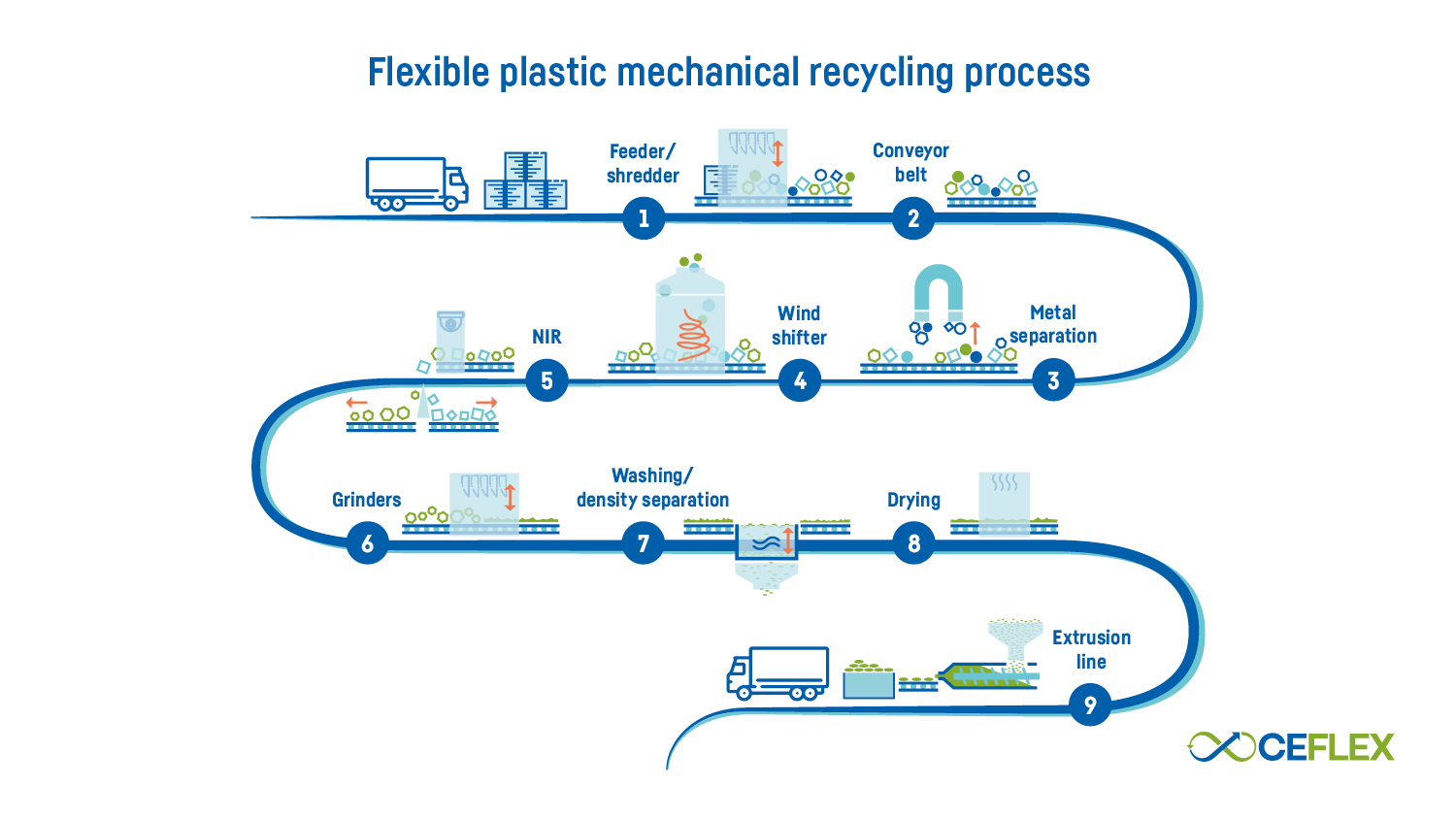

Generally, the recycling of household flexible plastic follows three basic steps: collecting, sorting, and processing. First, plastic waste is collected and brought to waste processing plants. Secondly, the plastic waste is sorted into batches of uniform plastics with a variety of techniques, as seen in Figure X (steps 1 to 5). The sorting begins with the removal of any scrap metals, then flexible plastics are separated from the rigid plastics (with many small pieces being discarded in the process), and lastly the types of plastic material are divided into uniform batches (e.g., PE, or multi-materials) through near infrared (NIR) sorting machines. After sortation, the uniform plastic bales can be brought to plastic material specific processing plants. The processing of these plastics includes shredding into flakes, washing, and finally melting into manufacturing-ready granulates (Step 6 to 9 in Fig. X). These granulates are used to produce new plastic products. For a video of this process, see how it is done at Suez, a Dutch waste company.

We have multiple recyclable packagings. To view them, go to Designed for recycling (plastic) of Designed for recycling (paper).

Bioplastics: Bio-based, biodegradable and compostable plastics: what are they, and what are their differences?

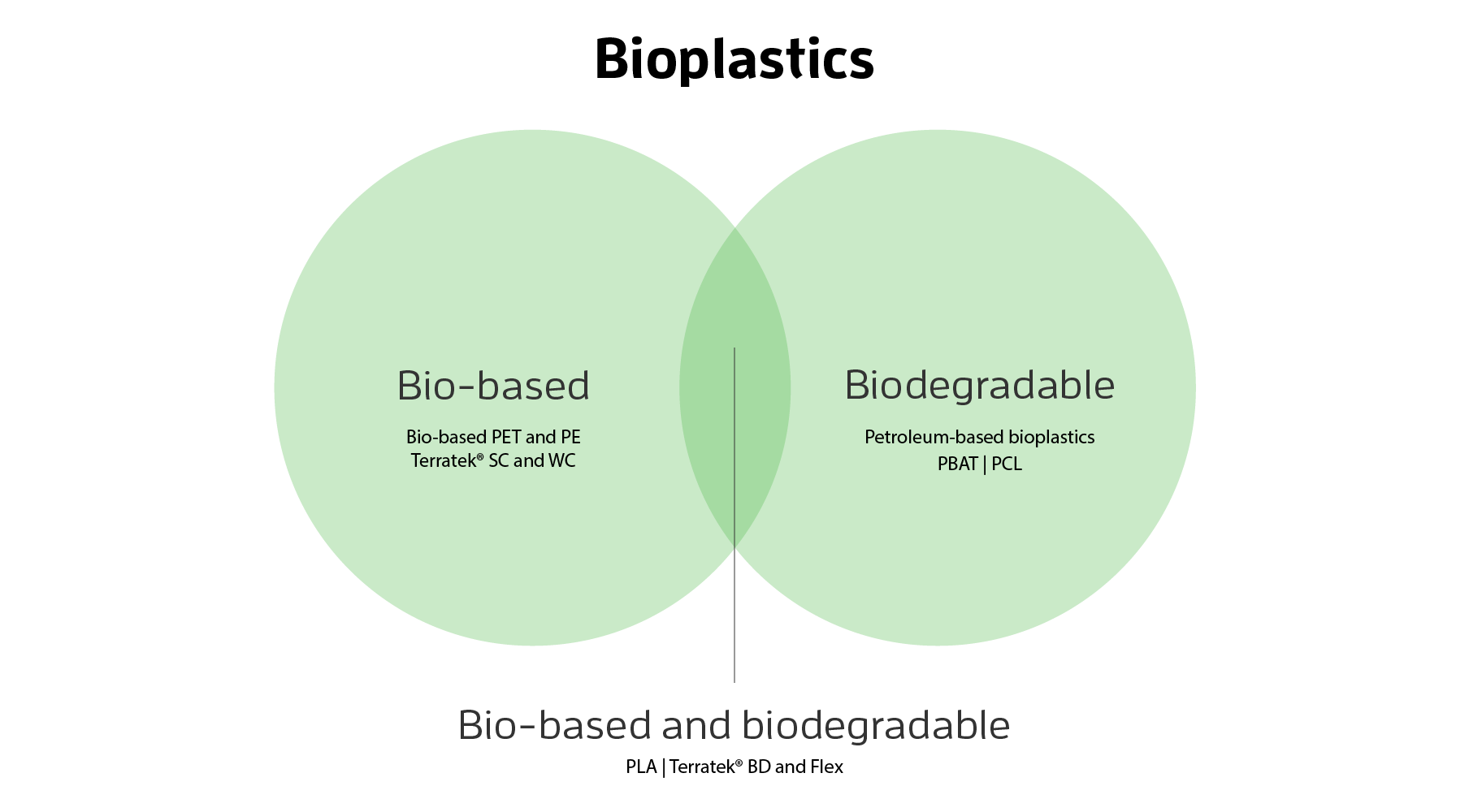

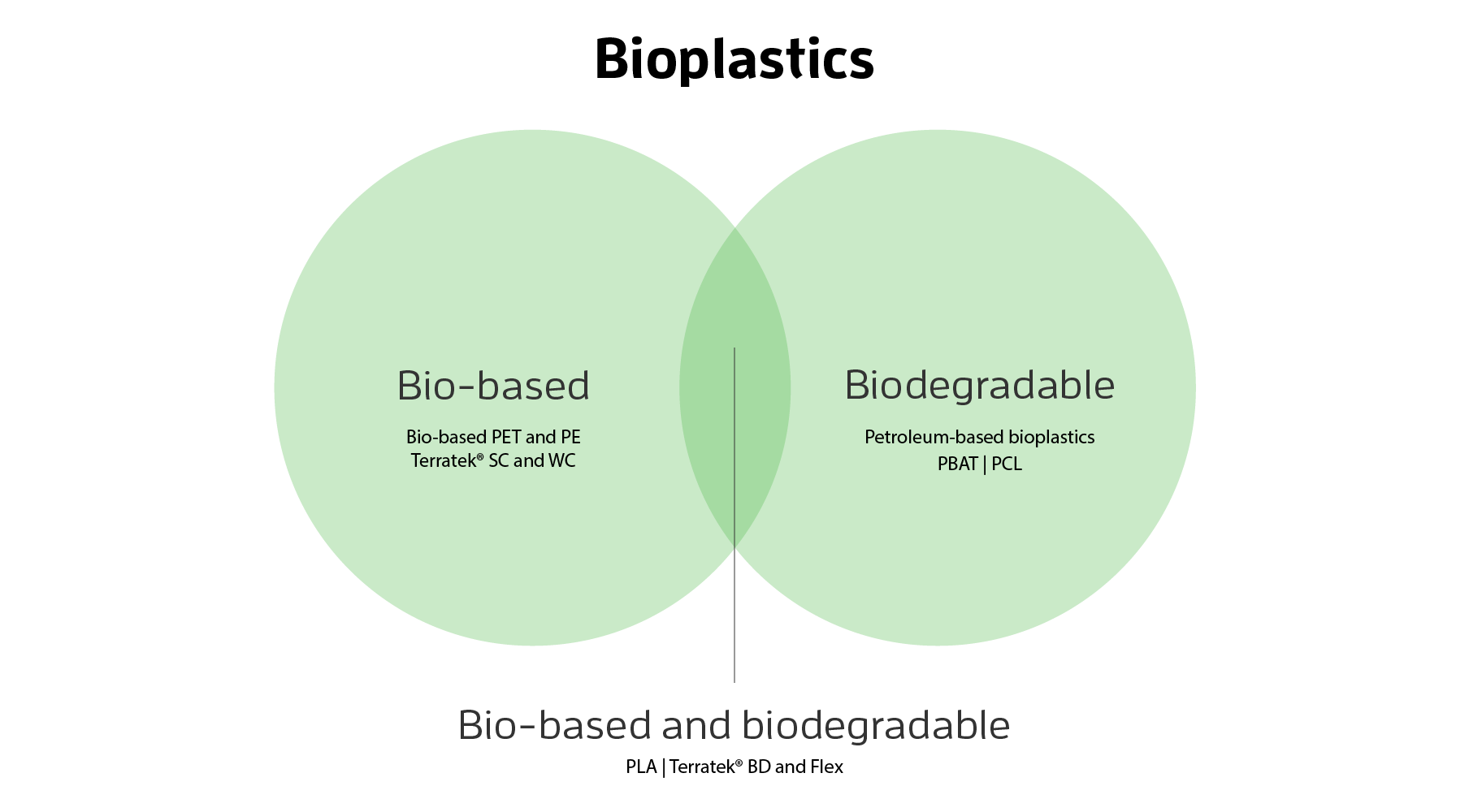

Bioplastics are a promising solution to reduce some of the negative environmental impacts of plastics. However, there is some confusion around some of the terms used when talking about bioplastics, but they have very different meanings and need to be used carefully:

- Bioplastics are a large family of plastics that are either made from renewable materials (bio-based), or that can biodegrade into organic matter at the end of life (biodegradable), or both (bio-based and biodegradable).

- Bio-based plastics are a type of bioplastics. Bio-based plastics are made from renewable materials (plants) instead of fossil fuels.

- Biodegradable plastics are a relatively small subset of bioplastics. They can be converted into water, carbon dioxide (CO2) and biomass over time, with the help of microorganisms. This process is called biodegradation. The biodegradability of a plastic lies with the chemical properties of the polymer –and not the raw material it is made with– biodegradable plastics can be either bio-based or fossil-based. Nearly every material will biodegrade, given enough time. The length of biodegradation is highly dependent on environmental parameters such as humidity and temperature. Claiming that a plastic is ‘biodegradable’ without any further context (i.e., in what timeframe and under what environmental conditions) is not a guarantee of anything and is a misleading claim.

- Compostable plastics are a subset of biodegradable plastics defined by the standard conditions and timeframe under which they will biodegrade. They have been tested to adhere to international standards such as EN-13432 for biodegradation in an industrial composting facility environment. All compostable plastics are biodegradable, but not all biodegradable plastics would be considered compostable. Unless specifically mentioned, compostable plastic will not decompose at home or if littered in nature. It is important to note that most countries do NOT treat organic waste in the industrial composters that compostable plastics require and instead use anaerobic digesters. In those cases, compostable plastic does not biodegrade properly. Check here to see which countries have the infrastructure to compost compostable plastic.

Therefore, bioplastics can be classified into:

- Non-biodegradable bio-based plastic (also known as drop-in bio-based plastic): these plastics are exactly the same as conventional plastics and can directly substitute them in all their applications (they have the same chemical structure and properties), but are made with plants. For example, bioPE is a drop-in bio-based plastic usually made from sugar cane. BioPE has the same properties as normal PE and is therefore recyclable in some countries (just like PE), but it is NOT biodegradable (just like PE).

- Biodegradable and fossil-based

- Biodegradable and bio-based plastic: these plastics are also made with plants, and they can also biodegrade at their end-of-life. For example, PLA is made from sugarcane and it can biodegrade in industrial composting facilities (i.e., it is compostable).

Source: Green Dot Bioplastics

We have multiple bio-based and compostable packagings in our range.

When is flexible plastic packaging recyclable?

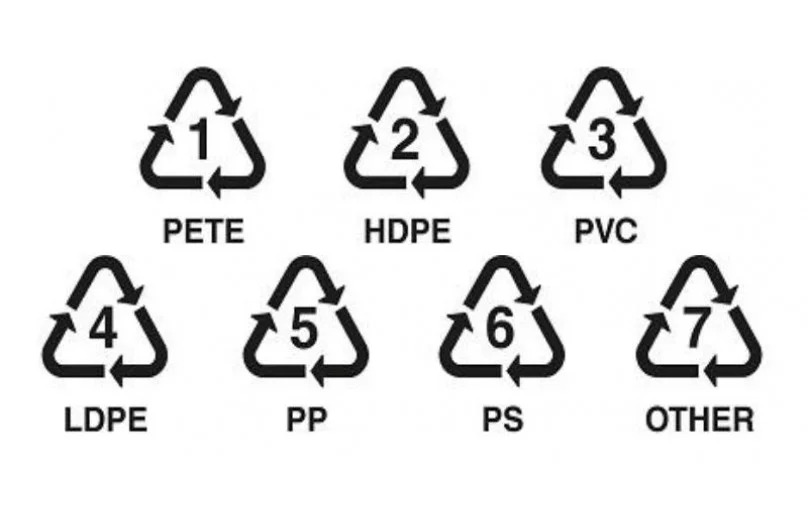

To check the recyclability of a flexible plastic packaging product, there are a few criteria to consider:

- It should contain only plastic materials (no metal or paper, for example. Be aware of packaging like potato chip bags that have an inner flexible aluminum layer).

- It should not be colored black.

- It should be larger than 5x5cm.

- It should not contain any rigid parts, such as a hard plastic spout and cap.

- It should be mono-material PE.

- Ideally, it should not contain any extra elements such as barriers, coatings, and/or fillers.

- Ideally, any adhesives should be soluble in cold water.

- Check if it fits the specific criteria for the relevant local recycling infrastructures per country (click here for an overview).

See for further detail the ‘Recycle Check Flexible Plastic Packaging’ of the Netherlands Institute for Sustainable Packaging (KIDV).

Our products with the eco-label 'Designed for recycling' on the website also meet the criteria. Go to Designed for recycling (plastic) or Designed for recycling (paper) for the products and look here for an explanation of the eco-label for more information.

What can I recycle in my country?

See here what types of flexible plastic products are recyclable in The Netherlands, United States, United Kingdom, Germany, France, Denmark, Sweden, Norway, and Spain.

What is recycled content and why do we use it?

Recycled content refers to the portion of materials used in a product that comes from the solid waste stream. If those materials are diverted during the manufacturing process, they can be referred to as pre-consumer recycled content (or post-industrial). If they are diverted after consumer use, they are post-consumer recycled content.

Using recycled content in flexible plastic packaging has a significant impact on plastic pollution as it reduces the extraction of virgin plastics, conserves natural resources, and saves energy. Moreover, increasing the use of recycled content incentivizes and strengthens the recycling system by keeping plastics and paper in use and minimizing the amount of materials sent to landfill and incineration or ends up in the ocean.

The increasing use of recycled content in flexible plastic packaging is being promoted by governments throughout Europe and across the world. In particular, as part of the Green Deal, the EU Commission plans to introduce a minimum quota for the usage of recycled content. The Commission is still determining specific percentage requirements, however the quotas are expected to reach up to 30% by 2030. The EU Circular Economy Action Plan also introduces legislation for the minimum use of recycled content by 2022 at the latest. Several national governments have already taken action, such as in the UK where a tax has been implemented on plastic packaging that does not contain at least 30% recycled content.

We have made multiple packagings from recycled content. Click here to view them.

What is new plastic or virgin plastic?

Virgin plastic is plastic that has been made from raw materials, and that has no recycled content. The raw material of virgin plastics can either be non-renewable fossil fuels (petroleum-based plastic) or renewable plant-based materials (bio-based plastic).

What considerations should be made when designing my packaging to keep it fully recyclable?

Recyclable packaging can be accidentally made unrecyclable, but easy decisions can be made to ensure that packaging is optimally recyclable.

When developing fully recyclable plastic packaging, attention should be paid on two levels: the design of base packaging product and the additions made: On the first level of considering the base product’s design, four criteria need to be fulfilled to develop a fully recyclable packaging:

- The product is made out of the mono-material LDPE or PP,

- The product is non-black,

- The product is free of rigid plastic components,

- The product is larger than 5x5 cm.

On the second level of consideration of what is added to the packaging, attention should be paid on the choice of labels, inks, and adhesives that are going to be incorporated to the plastic packaging.

Labels

According to KIDV’s Recycle Check Flexible Plastic Packaging (2021), as a rule of thumb, labels should be made from the same material as the packaging. Otherwise it is difficult to separate the label from the main packaging, regardless of the label’s potentially washable character. Therefore, if the main component of the packaging is PE, then the label should be LDPE as well to be optimally recycled. If a label is made from a different material than the main component, it should cover no more than 30% of the surface to which they are attached. This ensures the Near Infrared (NIR) sorting machine will identify the material of the main packaging and not of just the label. Additionally, any metallic or paper label in plastic packaging hinders the recycling process.

Adhesives

Adhesives and hotmelts used to attach labels to the packaging should be low-temperature washable adhesives, so that they will not inhibit the recycling process. Generally, any type of adhesive needs to be soluble in cold water.

Inks

For inks to be compatible with the recycling of LDPE and PP products, they need to make up less than 5% of the packaging’s total weight and should be both water-based and water-soluble. Additionally, black ink should not cover a majority of the packaging to not interfere with the NIR sorting machines.

We have multiple recyclable packagings. To view them, go to Designed for recycling (plastic) or Designed for recycling (paper).

Why include products in our sustainable eco-labels which do not currently fit into the worldwide recycling infrastructures?

As the recycling industry innovates continuously and various companies and governments have announced support for new, coordinated recycling efforts, we also chose to align our considerations of sustainable materials with ongoing initiatives. By designing products aligned with these initiatives, DaklaPack supports the economics of these recycling innovations. This is an important step as it is currently not possible to design all packaging products for recyclability under current infrastructures without sacrificing product quality. Recycling initiatives, like the Circular Economy for Flexible Packaging (CEFLEX,) which is a collaboration of over 160 European companies, associations and organisation also highlight the need to support currently recyclable materials (PE) and for materials in line with future recycling systems (PP).

We have multiple recyclable packagings. To view them, go to Designed for recycling (plastic) or Designed for recycling (paper).

What is the difference between coating, varnishing and adhesives?

Coatings, varnishes, and adhesives are commonly used in paper and plastic packaging. However, there is often confusion around their definitions. Quick definitions can be found below.

Coating is an umbrella term that refers to any layer which is applied on paper or plastic material. Coatings usually have a functional or a decorative purpose and can cover all or part of the plastic or paper material. An example of a functional coating is an adhesive used to attach a label to a packaging product. Other functional coatings are most commonly used to enhance the surface properties of the packaging, such as moisture resistant coatings intended to increase the shelf life of food products. Coatings can be used for decorative purposes such as enhancing the printability of a packaging product. Varnishes are also coatings with decorative purposes (see below).

Adhesives (Glues) are substances which attach different layers of paper/plastic together. If adhesives are not water soluble or shape retaining they can create difficulties at the recycling process because they cannot easily be removed and thus can create ‘stickies’ that can clock the machines.

Varnishes are very thin protective layers often added to improve the appearance of a packaging product. Varnishes are a type of decorative coating, which are basically clear inks that can be satin, matte or glossy. When added to paper, varnishes act similarly to ink with the purpose of enhancing the appearance of packaging. Varnishes can increase the perceived quality of a product, but it is not eco-friendly as it can release toxic compounds when degraded and can make paper unrecyclable (see Logo “Not recyclable Paper”).

If you have any questions about this, please do not hesitate to ask us.

Paper VS. Plastic - When should you use what?

Neither plastic nor paper can be considered as a one-size-fits-all sustainability solution. It is important to assess and consider the packaging needs of each product to find the ideal package for you and the environment (for more details please don't hesitate to contact us).

The comparison of plastic and paper packaging has to consider both their manufacturing and their end-of life impacts. In terms of manufacturing, while virgin plastic is cheaper to produce, it is made from non-renewable fossil fuels. And while paper is made from renewable sources (usually wood fibers), the production process requires more water and energy than plastic. In terms of their end of life, paper benefits from a much more robust recycling rate. In Europe, 72% of paper was recycled in 2019 (CEPI) compared to 26-52% of plastic (Plasticseurope). The different recycling rates of plastic in Europe can be explained by the different collection schemes within Europe and the different available infrastructure (what is recyclable in your country see here.) and consumer behaviour. Therefore the end-of-life impact of plastic, especially flexible plastic appears to be a key sustainability issue.

However, plastic packaging is extremely important for reducing food waste and meeting the technical barrier needs of certain products. (For more information click here). liquid foods for example are better packed in plastic (ideal mono-LDPE - see Logo: Designed for Recyclability Plastic) because plastic provides better barrier protection than paper. Food in plastic packaging usually has a longer shelf life, reducing the significant sustainability impact of food waste.

Some products are incompatible with paper packaging due to paper’s low barrier properties. Greasy food, for example, decreases paper recyclability. In such a paper packaging needs to be composted instead, removing a majority of paper’s end of life benefits. Or alternatively, plastic packaging should be used instead. However, dry foods, like pasta, can easily be packed in paper packaging because it has a naturally long shelf life and does not need special packaging barriers.

To explore more of the advantages and disadvantages of paper versus plastic in scientific detail, a wide range of LCA (Life Cycle Analysis) studies can be read, such as the LCA of different grocery bags.

We have multiple plastic and paper packagings that fall under the label 'designed for recycling'.

How is paper recycled?

Every paper recycling mill is different and might have more or less steps in the process. However, most mills follow the same basic steps in paper recycling. After collection, separation technologies are used to remove other materials from the paper stream. Usually, after this process packaging in the paper stream is manually checked. Next, paper and cardboard are shredded and soaked in water which separates fibers in the paper, creating a create paper pulp mixture. Contaminations such as inks are often separately removed. The type of ink used in the paper has a major impact on the de-inking process because water-soluble and heat-sensitive ink can discolour the water and the pulp (the wet fibers), degrading or even completely ruining the entire batch.Therefore water non-soluble ink and non-heat sensitive ink should be used. These inks can be separated from the pulp and floated to the water tank’s surface for removal with a combination of air bubbles and toxin-free chemicals. Lastly, the pulp is dried and often mixed with virgin fibers to strengthen the new paper in a process called repulping.

A detailed description of the average recycling path of paper can be found at Cyclos HTP (2019) (click onsh d engliocument, pagina 61).

We have multiple paper packagings designed to be recycled.

When do I need to recycle and when do I need to compost paper packaging/products?

Paper has one of the most robust recycling systems, but it is also naturally compostable as it is made from wood pulp. The choice between recycling and composting paper products depends on any added features to the paper (e.g. plastic, coatings) and the cleanliness of the paper it's been used.

Ideally, paper should be recycled, (for the specific criteria for paper to get recycled please visit “Designed for recyclability - Paper). Recycling decreases the use of natural resources (mainly wood fibre), energy and water. However, if the paper packaging has been in contact with greasy foods (e.g. pizza in a cardboard box or a dirty paper towel) or if there is food residue in the packaging, it cannot be recycled anymore. In those cases, paper can always be home composted, and in some countries it can also be disposed of in the organic waste bin to avoid landfilling or incineration. To facilitate compositing, the paper packaging should be cut into small pieces before disposal. You can check what materials are accepted in the organic waste of your country here.

When is paper packaging recyclable?

To check the recyclability of a paper packaging product, there are a few criteria to consider:

- At least 95% of the materials used by weight is paper

- The coating is water-soluble or is only applied on one side of the paper

- The adhesives (glue) used is either ‘shape-retaining’ or ‘water-soluble’

- No varnish is used

- The Ink is non-water soluble, non-heat sensitive, and mineral-free

- It should not be colored black or any very bright color

- It should be made from wood fiber (vegetable-based substitutes are still being researched)

- It is not contaminated with food waste (e.g. grease in a pizza box or dirty paper towel).

For a detailed explanation of these criteria please check the Eco-label “Designed for Recyclability - Paper” and the FAQ question ”When do I need to recycle and when do I need to compost paper packaging/products?”.

The criteria above are based on recycling guides from the KIDV, CEPI, CPI or Greenblue.

We have multiple paper packagings designed to be recycled.

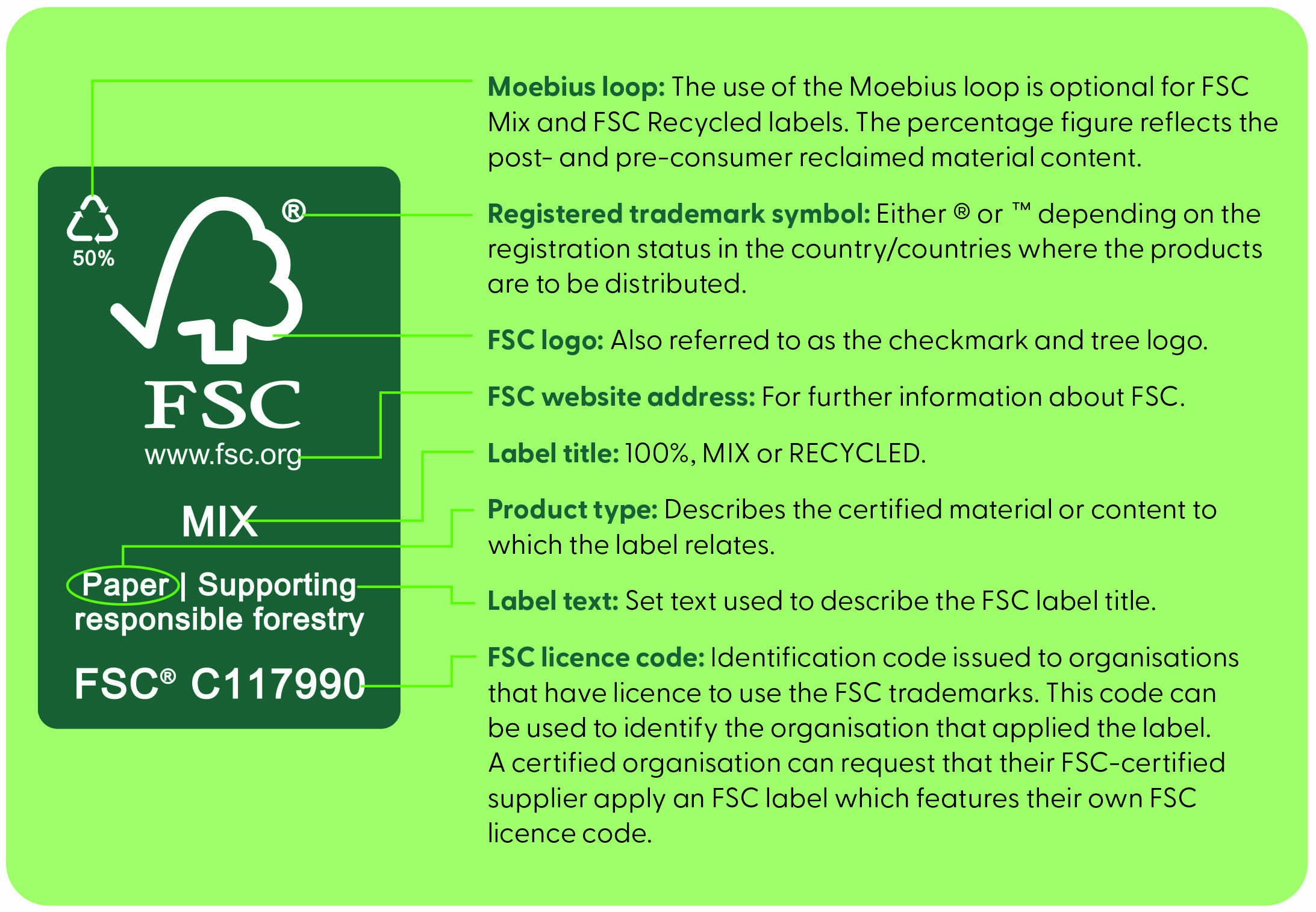

What does the FSC certificate on paper mean?

FSC stands for Forest Stewardship Council, an international non-profit dedicated to the sustainable use of wood. If paper is FSC certified, it has been proven to be manufactured in an environmentally, socially and economically sustainable way. There are three FSC labels: FSC 100%; FSC Mix and FSC Recycled.

FSC 100%: All the fibers used in this paper are sourced from a FSC-certified forest which is sustainably managed. These forests are independently audited to ensure that the principles and criteria of FSC are met.

FSC Mix: The fibers used in this paper are a mixture of one or more of the following: virgin fiber from a FSC certified forest, recycled fiber, or FSC controlled wood (while not certified, these fibers have been risk assessed by FSC standards to avoid undesired sources. More info can be found here). However, the paper product has to contain at least 70% of FSC-certified fiber.

FSC-gerecycled: All fiber used in this paper has to be either pre or post-consumer recycled, with at least 70% coming from post-consumer recycled fibers.

Source: https://uk.fsc.org/what-is-fsc/fsc-labels. (last accessed on 12th of May 2021).

+31 (0)320 277 907

+31 (0)320 277 907

info@daklapack.com

info@daklapack.com

5-10 Days delivery time

5-10 Days delivery time